Boats and water make a great pair, until electricity enters the picture. Corrosion sneaks up on wires and connectors, turning bright copper dull and brittle, and making small problems feel like big ones. The result can be flickering lights, false alarms, weak starts, and mystery faults that only show up when you least expect them. The good news? You can stop most of it with simple habits and the right parts. This guide breaks the topic into clear steps you can follow at home. We’ll focus on what causes the damage, what to install, how to lay it out, and how to keep it clean. No fluff, just practical ways to keep your boat’s electrical system healthy for the long run.

Why Boat Electrics Suffer From Corrosion Threats

Salt, moisture, and electricity form a tough trio. Salt water leaves behind a thin film that pulls moisture from the air. That damp layer turns metal surfaces into slow-moving chemical sites. Over time, bare copper darkens, connectors lose grip, and a once-solid circuit starts to heat and drop voltage. Even on lakes, spray, dew, and bilge vapor fuel the same pattern. Corrosion doesn’t always look dramatic. It can be tiny crystals inside a crimp, a green stain near the battery, or a chalky ring around a fuse. Each small change increases resistance and heat. Heat then speeds up the decay. That’s why a system can seem fine at the dock and act up under load on the water. To stay ahead of it, accept this simple rule: every connection is a possible entry point for moisture, and every metal mix (like copper to aluminum or stainless) can set off a reaction if left unprotected.

Watch for early clues.

- Switches that feel warm after use

- Lights that dim when you add another load

- Intermittent gauges or electronics resets

- Green or white powder near terminals

Choose Marine-Grade Wires And Cleaner, Safer Connections

Start with the right wire. Marine-grade, tinned copper wire fights corrosion better than bare copper. The thin tin layer slows oxidation, and the fine stranding handles vibration without breaking. Size the wire for the circuit length and load; a thicker cable reduces voltage drop and heat. For terminations, use crimp-on connectors designed for marine use. Heat-shrink, adhesive-lined terminals are worth it because they seal out moisture once shrunk. Avoid twisting and taping; those quick fixes invite water. You must join wires, use a sealed butt connector, or a proper terminal block with protective boots.

Connection tips that make a difference

- Strip wire cleanly; avoid nicking strands

- Use a quality ratcheting crimper, not pliers

- Apply heat evenly until the adhesive beads at the edges

- Finish exposed hardware with dielectric grease (thin film)

- Cap unused plugs and label both ends of each run

A small upgrade, like switching to tinned wire and sealed connectors, often solves “mystery” faults before they start.

Plan Layout, Drip Loops, And Sealed Enclosures

Moisture always follows the easiest path. Your layout should make that path end away from live parts. Add drip loops where cables enter panels or boxes: let the wire drop below the entry point and then rise, so water drips off before reaching the fitting. Keep junctions high and dry, not low in the bilge. Where you must place gear near damp zones, mount it on a raised panel with air space behind it. Use sealed enclosures for fuse blocks and bus bars; gaskets and proper strain relief cut down on moisture migration.

Smart layout habits

- Separate power cables from steering and fuel lines

- Keep high-amp runs short and direct

- Use grommets where wires pass through metal or fiberglass

- Zip-tie in gentle curves, not tight bends, to protect insulation

- Choose IP-rated boxes for splash areas, and face openings downward

By steering drips away and sealing entry points, you keep corrosion from ever reaching sensitive parts.

Keep Moisture Out With Simple Routine Care Steps

No product can beat steady care. Salt film and bilge vapor settle on everything, so plan quick routines. Wipe exposed terminals with a damp cloth and then dry. Reapply a light coat of dielectric grease on battery posts and open connectors. Open enclosure lids and check gaskets for grit that might break a seal. Vent the cabin and engine space after use to clear humid air. If you store the boat, lift cushions, support locker lids slightly, and remove portable electronics to keep connections dry.

A simple monthly checklist

- Rinse battery tops; keep them clean and dry

- Snug terminal screws (not over-tight) and replace cracked boots

- Look for chafed insulation and add split loom where needed

- Clear drain paths so water doesn’t pool near wiring

- Refresh labels that are smudged or peeling

These short tasks take minutes and block the slow creep of corrosion that causes big headaches later.

Test Often And Track Issues Before They Grow

A basic multimeter is your best friend. You don’t need advanced settings; just learn to check voltage, continuity, and simple resistance. Test voltage at the battery, at the panel, and at the device when it’s running. A large drop across a connection point to hidden corrosion or a weak crimp. Continuity tests help find broken wires that look fine on the outside. Keep a small log in your toolbox or phone: note what you tested, what you saw, and what you changed. Patterns appear fast when you write things down, and repeat issues become easier to spot.

Helpful testing habits

- Test under load; problems often hide until current flows

- Wiggle suspect wires gently while measuring for flickers

- Check fuse clips and breakers for warmth after use

- Keep spare fuses, sealed connectors, heat-shrink, and a crimper onboard

- Photograph tricky areas before you take them apart

Regular tests catch weak spots early, saving both time and parts.

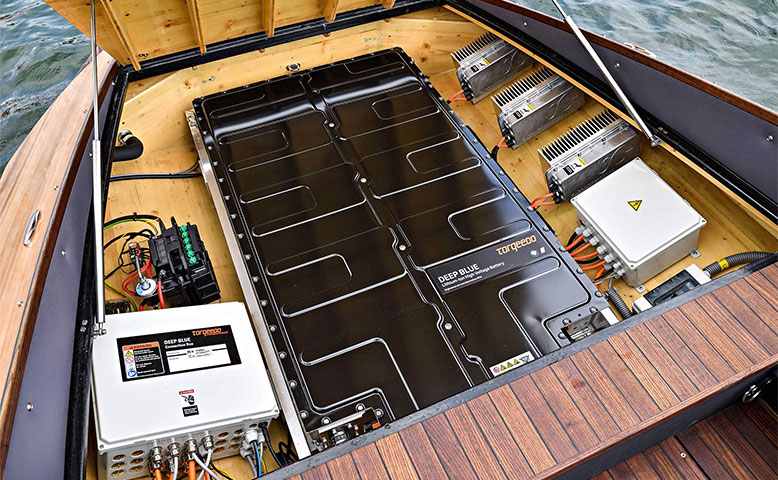

Protect Batteries, Chargers, And Shore Power Gear

Batteries are the heart of the system, and they crave clean, tight, protected links. Use proper battery boxes or trays with hold-downs, and install terminal boots. Keep charger leads short and sized for the output. Smart chargers designed for marine use are gentler on batteries and usually include better protection against moisture. Inspect shore power cords for nicks and burned blades; heat marks mean you should replace the end or the cord. At the inlet, check the gasket and strain relief so spray can’t creep into the back of the plug.

Battery and shore tips

- Clean posts, then fit locking washers and boots

- Route charger wires away from the exhaust and moving parts

- Coil shore cords loosely; never wrap them tight around a hook

- Keep a spare inlet gasket and a spare cord end

- Label charger profiles so the right battery gets the right setting

When your power sources are tidy and sealed, the rest of the system benefits.

Conclusion

Staying ahead of corrosion is about smart parts, clean layouts, and steady care. Choose marine-grade wire, seal every joint, plan drip loops, and test under load. Write down what you change so you can spot patterns. If a problem keeps returning or you prefer a pro set of hands, reach out to local experts who work on boats every day. Just N Case Auto Marine & RV offers auto repair, RV repair, boat repair, trailer repairs, and truck repairs. A quick chat or seasonal inspection could keep your next trip smooth, your lights bright, and your start strong.